QUALITY, RELIABILITY, AND DURABILITY

Skyjack products are manufactured, sold, and supported worldwide and our scissor lifts are internationally known for their simple reliability. Skyjack is a manufacturer known for offering the rental industry with the best lifecycle value.

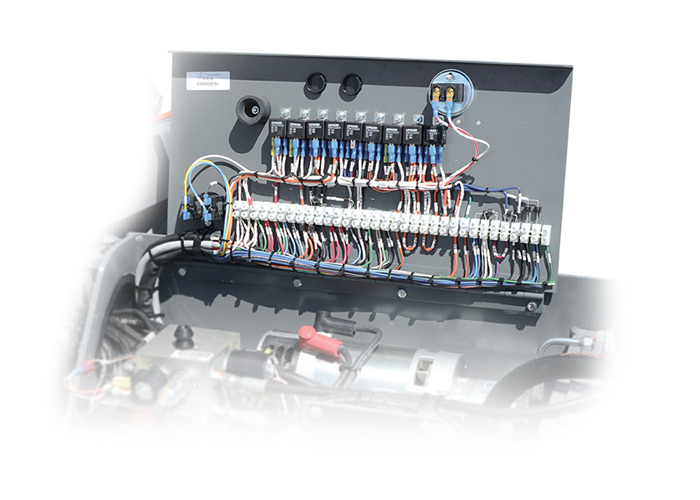

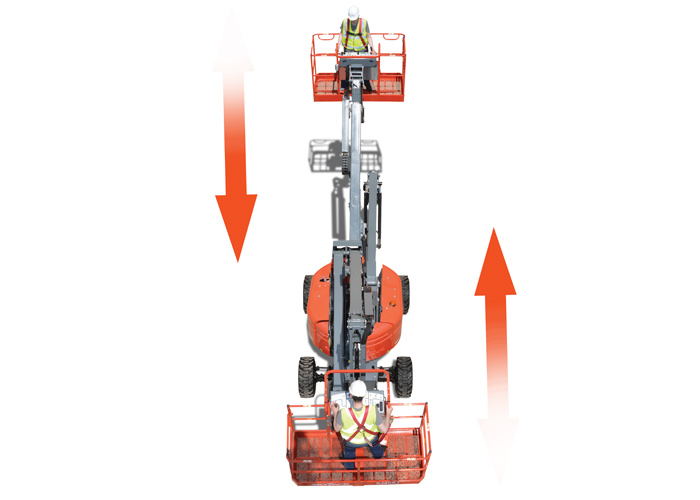

UNIQUE FEATURES

Skyjack recognizes that having user-friendly equipment that can withstand the harsh demands of the rental industry is critical to increasing our customers’ utilization rates. In order to create rental products that are truly unique and add value to our customers, Skyjack employ a collection of trademarked features that are only available on our products.